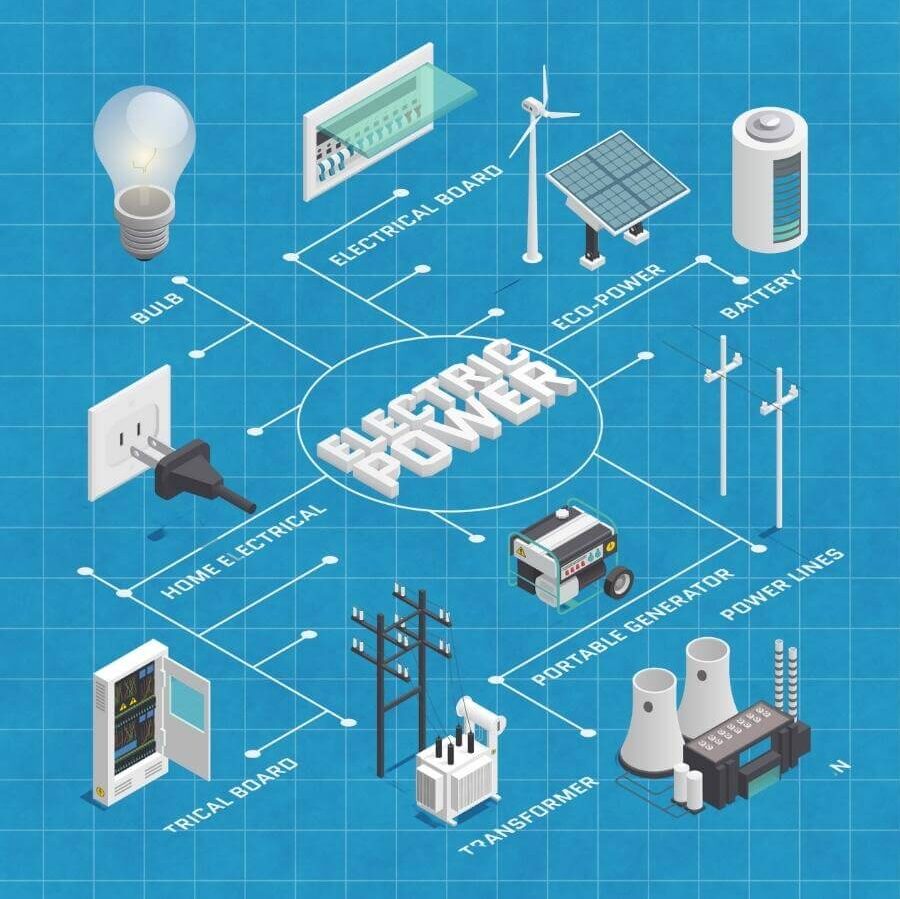

What is Electric Power System?

Electric Power System is a combinational network that interconnects the establishments for generation, transmission, distribution, and load(industrial, commercial, residential) of electrical power. In this process, the energy source (such as coal, diesel, and uranium) is converted into electricity. In a power system, many devices are connected, such as the synchronous generator, motor, transformer, relay, circuit breaker, conductor, etc.

Four major parts can be found in a power system:

- Generation

- Transmission and sub-transmission

- Distribution

- Loads

Generation

Electric power is generated at a generating station based on load requirements. In order to generate electric power, a generating station uses a prime mover coupled with an alternator. The prime mover (e.g., steam turbine, water turbine, etc.) converts energy from some other form into mechanical energy. An alternator takes the mechanical energy from the prime mover and converts it to electrical energy. The produced electrical energy is transmitted and distributed with the help of conductors to various consumers. Apart from the prime mover and alternator combination, a modern generating station utilizes many auxiliary devices and equipment to ensure a reliable, consistent, and affordable electricity supply.

Generation stations are classified according to the form of energy they convert into electrical energy:

- Steam Power Station: It converts the heat energy of coal combustion into electrical energy.

- Hydro-electric Power Station: A generating station located in hilly areas that uses the potential energy of water to generate electrical energy is called a hydro-electric power station.

- Diesel Power Station: In a diesel power station, diesel burns inside the engine and the products of this combustion act as the “working fluid” to produce mechanical energy. The “Diesel engine” drives the alternator which converts mechanical energy into electrical energy.

- Nuclear Power Station: A generating station in which nuclear energy is converted into electrical energy is known as a nuclear power station.In nuclear power station, heavy elements such as Uranium (U235) or Thorium (Th232) are subjected to nuclear fission* in a special apparatus known as a reactor. The heat energy thus released is utilized in raising steam at high temperature and pressure. The steam runs the steam turbine which converts steam energy into mechanical energy. The turbine drives the alternator which converts mechanical energy into electrical energy.

Transmission and sub-transmission

The purpose of an overhead transmission network is to transfer electric energy from generating units at various locations to the distribution system which ultimately supplies the load. Transmission lines also interconnect neighboring utilities which permit not only economic dispatch of power within regions during normal conditions, but also the transfer of power between regions during emergencies. Standard transmission voltages are established in the United States by the American National Standards Institute (ANSI). Transmission voltage lines operating at more than 60 kV are standardized at 69 kV, 115 kV, 138 kV, 161 kV, 230 kV, 345 kV, 500 kV, and 765 kV line-to-line. Transmission voltages above 230 kV are usually referred to as extra-high voltage (EHV).

The portion of the transmission system that connects the high-voltage substations through step-down transformers to the distribution substations is called the sub-transmission network. Typically, the sub-transmission voltage level ranges from 69 to 138 kV. Some large industrial customers may be served from the sub-transmission system. Capacitor banks and reactor banks are usually installed in the substations for maintaining the transmission line voltage.

Distribution

The distribution system is that part that connects the distribution substations to the consumers’ service-entrance equipment. A typical distribution system consists of a step-down transformer (e.g., 132/11 kV or 66/11 kV or 33/11 kV). The primary distribution lines are usually in the range of 4 to 34.5 kV and supply the load in a well-defined geographical area. Some small industrial customers are served directly by the primary feeders. The secondary distribution network reduces the voltage for utilization by commercial and residential consumers. Lines and cables not exceeding a few hundred feet in length then deliver power to the individual consumers. The power for a typical home is derived from a transformer that reduces the primary feeder voltage to 240/120 V using a three-wire line. Distribution systems are both overhead and underground.

Loads

Loads of power systems are divided into industrial, commercial, and residential. Very large industrial loads may be served from the transmission system. Large industrial loads are served directly from the sub-transmission network, and small industrial loads are served from the primary distribution network. The industrial loads are composite loads, and induction motors form a high proportion of these loads. These composite loads are functions of voltage and frequency and form a major part of the system load. Commercial and residential loads are independent of frequency and consume negligibly small reactive power.

The real power of loads is expressed in terms of kilowatts or megawatts. The magnitude of the load varies throughout the day, and power must be available to consumers on demand. The daily-load curve of a utility is a composite of demands made by various classes of users. The greatest value of load during a 24-hr period is called the “maximum demand”. Smaller peaking generators may be commissioned to meet the peak load that occurs for only a few hours. In order to assess the usefulness of the generating station, the “load factor” is defined. The load factor is the ratio of average load over a designated period of time to the peak load occurring in that period. Load factors may be given for a day, a month, or a year.

In general, the types of load can be divided into the following categories:

- Domestic Load: Domestic load mainly consists of lights, fans, refrigerators, air conditioners, mixers, grinders, heaters, ovens, small pumping motors, etc.

- Commercial Load: Commercial load mainly consists of lighting for shops, offices, advertisements etc., fans, heating, air conditioning, and many other electrical appliances used in commercial establishments such as marketplaces, restaurants, etc.

- Industrial Loads: Industrial loads consist of small-scale industries, medium-scale industries, large-scale industries, heavy industries, and cottage industries.

- Agriculture Loads: This type of load is mainly motor pump-sets load for irrigation purposes.